Transmissiemotor 12 kg/cm 12VDC 324:1 18RPM JGY-370

€ 13,12 incl. BTW

- Beschrijving

- Aanvullende informatie

- Q & A

Beschrijving

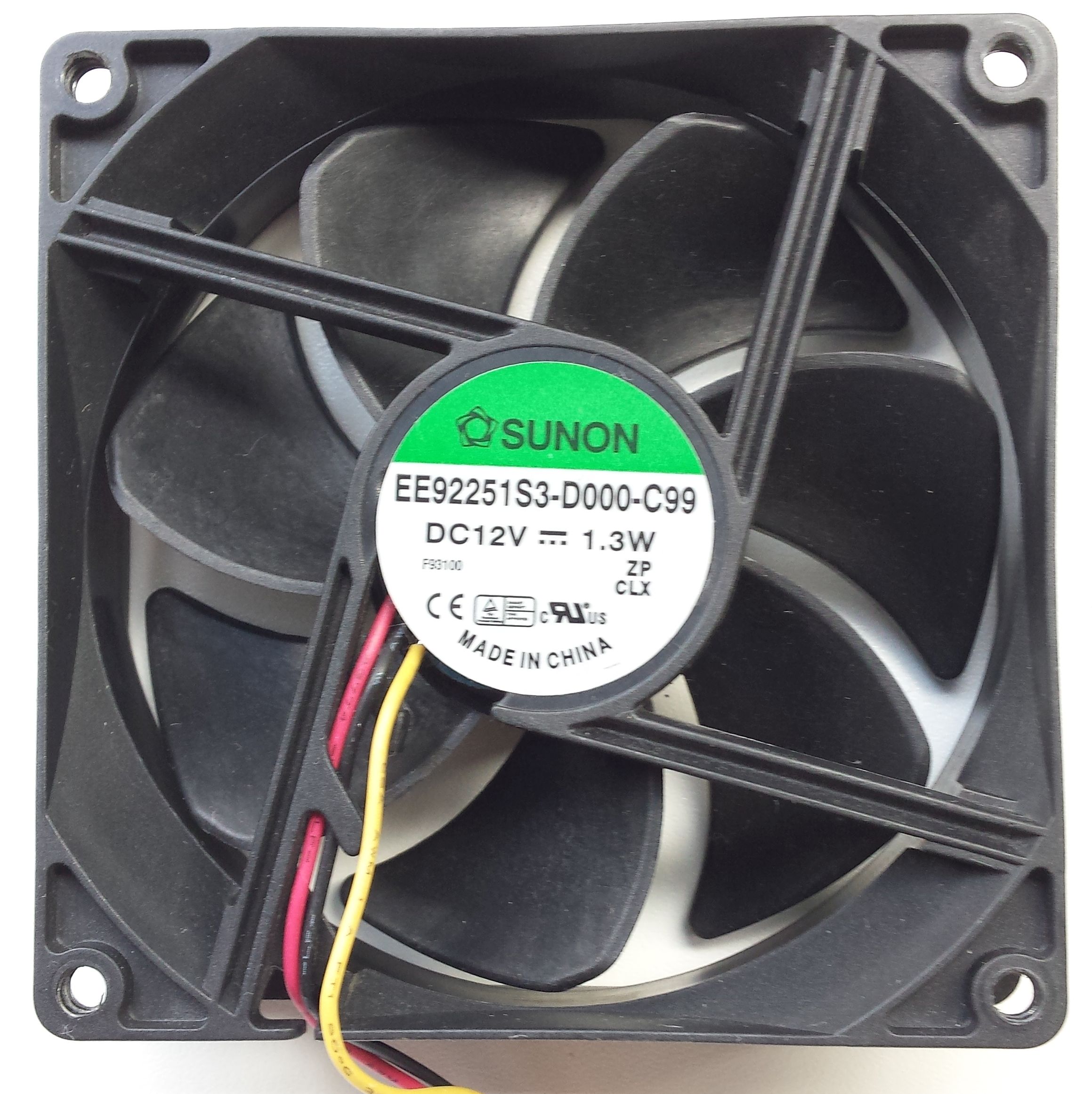

JGY370 Low speed DC motor with worm metal gearbox for high torque application like 4wd arduino robotic car,dc motorized curtains, smart window opener. JGY370 motors are permanent magnet motors known for delivering high power in a compact, portable package. JGY-370 DC motors Ideal for applications requiring motor speed adjustment and reversing capabilities.

Good quality and long lifetime, High torque and Low nosie.

JGY370 worm gear motor has the function of self-locking in power failure. The maximum bearing capacity of the gear is about 30KG.

About quality : High precision all – toothed gears , low noise , zinc alloy die – cast alloy pressure shell , stainless steel hardened Output shaft.

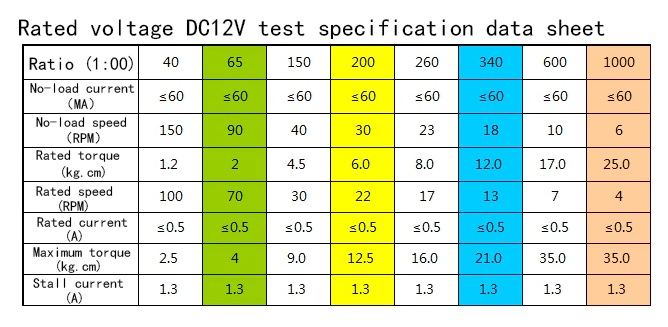

Specifications

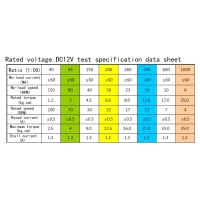

- Voltage range : DC 6V, 12V, 24V

- Available RPM/Speed range : 2,3,6,10,14,18,23,30,40,55,90,130,150,210

- torque Range in Kg/cm: 1.2-25Kg/cm

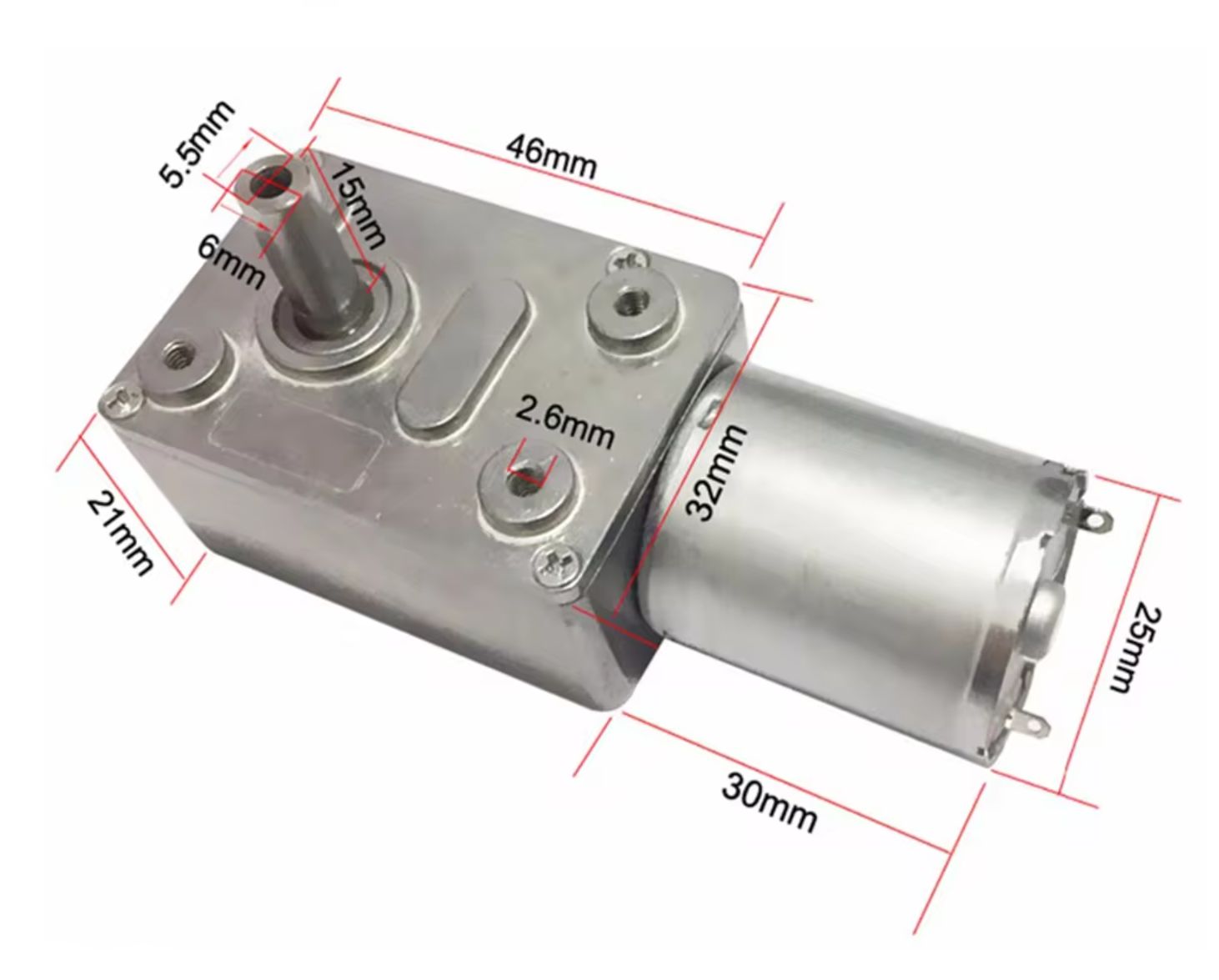

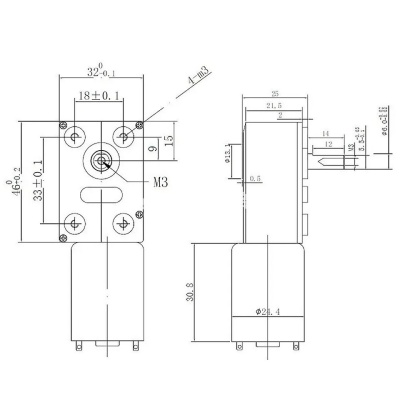

- GearBox: Rectangle micro-turbine worm gear box with Max bearing capacity 30Kg/cm and with self-lock at power failures.*The reducer output shaft arranged vertically with the motor shaft, whole motor output shaft relatively-short than general gear motor

- Motor Shaft :D Shape right angle stainless steel hardened Shaft 6mm ×15mm

- Opration: CW/CCW , you can change the wiring-connection to change motor rotation.

About the motor: Turbo worm deceleration and deceleration, all-metal gears can be used with the speed controller to control the speed (controllable range 0-select

The fixed air speed can be reversed and the motor can be reversed and returned (replace the motor terminal block positive steel plate change positive or negative or match the store speed adjustment

With positive and negative special speed regulator, forward and reverse switch). JGY370 turbo worm motor has a power-off self-twisting function and the largest gear.

The bearing capacity is about 30KG. For the human body parameters, please refer to the following parameter table size circle. If you have doubts, you need more parameter sizes, etc.

Tolerances

- Pay attention to the range of voltage and current used , use the motor in the case specified in this standard , otherwise

The life of the motor will drop. - Handling the motor: Take it lightly and use the outer casing of the motor as much as possible.

- Motor wiring: The red lead is connected to the positive pole, and the black lead is connected to the negative pole. If the reverse motor is rotated in the opposite direction.

- Overload : Use as much as possible within the load range specified by our company. It is forbidden to block or close the motor.

The state will run for a long time, otherwise the motor will burn out. - Motor Storage : Storage Temperature : 0″C-40″C, Storage Humidity: 15%-90%RH Avoid placing in high temperature, high humidity and corrosive gases.

- Motor usage temperature : 0″C-70″C

Limitations

- When you use the motor, there is no restraint. If the lubricant does not flow through the bearing through the rotating shaft, it will hinder the operation of the motor.

- The rotation of the shaft may have the opposite effect on the life of the motor. For the extension of the life, please check if your load is in accordance with the regulations.

It is not allowed to be overloaded or the end of the shaft is hung with items that hinder the rotation. - Manufactured as an eccentric heavy radiation load, the life of the harmful motor.

- Please do not store in high temperature or extreme humidity for four weeks , please do not place it in corrosive gas , which will reduce the motor effect .

- Do not run the motor in the surrounding high temperature and humidity.

- When soldering the motor terminals of the positive and negative poles of the power supply, the temperature of the soldering iron should be 340″C+40%C, and the heating time should not be within 3 seconds.

Plastic deformation causes the solder point to flow into the motor or break the end of the wire during operation, which can degrade the motor function. - Do not allow the motor shaft to get stuck. When power is transmitted, the motor will be overheated and burned out in a short period of time.

- It is impossible to guarantee the quality of the workman, so that the motor meets the instructions mentioned in the book, or the apparent judgment is obviously a fault.

Quantity - The supply is regulated by electricity, and the reliability is within the measurable requirements.

- Install the pulley or gear without abnormal aggravation when pressing in.

- When the motor is installed, the screw is too long, which will cause contact between the motor itself and the rotor, which will affect the characteristics.

Widely used for

- Household appliances and products,

- Office equipment,

- Health equipment and medical equipment.

- Beauty and fitness equipment,

- High-end toys and gifts,

- Electric tools,

- Automatic window sprayers,

- Robotic cars

- Automated facilities,

- Intelligent home automation systems,

- Industrial automation controls,

- Industrial drive assemblies.

Aanvullende informatie

| Gewicht | 1000 g |

|---|---|

| Afmetingen | 38 × 38 × 50 mm |